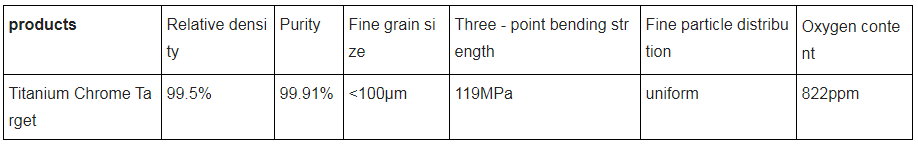

Pvd titanium chrome target

Chromium (Cr) is a silver-white metal with a bluish tint. Chromium in the atmosphere has a strong passivation ability, can maintain the luster for a long time, chromium to a variety of acid and strong alkali has a good corrosion resistance, chemical stability. Chromium also has high hardness, high resistivity and other characteristics. Due to various characteristics of chromium, chromium and its alloy or compound film layers prepared by various surface technologies have been widely used in surface engineering, such as: mechanical functional film layer, microelectronic film, electromagnetic functional film, optical film, decorative functional film layer and so on. With the development of high and new technology, high-purity chromium alloy sputtering targets with different performance and requirements are needed in the technical fields of microelectronic semiconductor integrated circuit, large curtain wall glass and automobile rear-view mirror.

Sputtering coating is to use sputtering phenomenon to achieve the purpose of making various thin films, that is, to use charge energy to bombard the surface of target material in a vacuum chamber, so that the bombarded particles deposit on the substrate to form a thin film. Magnetron sputtering coating has many advantages, such as good adhesion, compact film quality, water and electricity saving, and no waste treatment.

Vacuum degassing

Adopts 200 yard, and purity of 99. 95 wt %, oxygen content of 718 PPM of chromium powder, titanium powder (requirements - 200 mesh, purity is more than 99. 9%, oxygen content of 990 PPM) as raw materials, chromium powder, titanium powder charge weight ratio of 9:1, mixing, first of all, pressure of 5 mpa, to ensure that in the process of vacuum powder will not overflow in great quantities, in vacuum for Κ Γ 3 environment, with 300 ° C/h heating rate rose to 650 ° C, thermal insulation for 1 hour, filling the argon gas.

Phase temperature rise and pressure rise

In order to ensure the flow and bonding of chromium materials in the high-temperature sintering process, the hot-pressing process adopts the method of multi-stage heating and pressure to complete the sintering. Pressurized to lOMPa, then heated to 1050°C at a heating rate of 150°C /h for 1 hour, and then heated to 1400°C at a heating rate of l °C /h for 1 hour. Starting from 1100°C, 2MPa pressure was increased every 50°C during the temperature rise. The heating cut-off temperature was 1400°C, and the final pressure was 40MPa.

The holding furnace cooling

Release pressure, stop heating, and cool the target with the furnace.

Hot forging

In order to ensure the uniformity of internal grains, fine grains and even density distribution of the target, hot forging was carried out on the target after hot pressing. The forging temperature was l °C and the deformation rate was 0.3% /min.

annealing

In order to eliminate the residual stress inside the target during the hot forging process, the stress-relieving annealing was carried out at 300°C ~ 700°C for 3 ~ 5 hours.

Hot rolled

According to the different shapes of the target, the rotary hot binding method was used, the hot rolling temperature was 1200°C, and the curve deformation rate of milk was 6%.

Annealing: stress-relieving annealing at 400°C for 4 hours;

VID, machining to obtain chromium target products.

Hot Tags: PVD titanium chrome target, China, manufacturers, suppliers, factory, buy, customized, bulk, brands, in stock, Electronic Tungsten Wire In Coil, Tungsten Heater Wire Rope Coil, High Purity Round Tantalum Bar, 99 95 Purity Molybdenum Plate, Inconel Plate Sheet, Nickel And Alloy Material